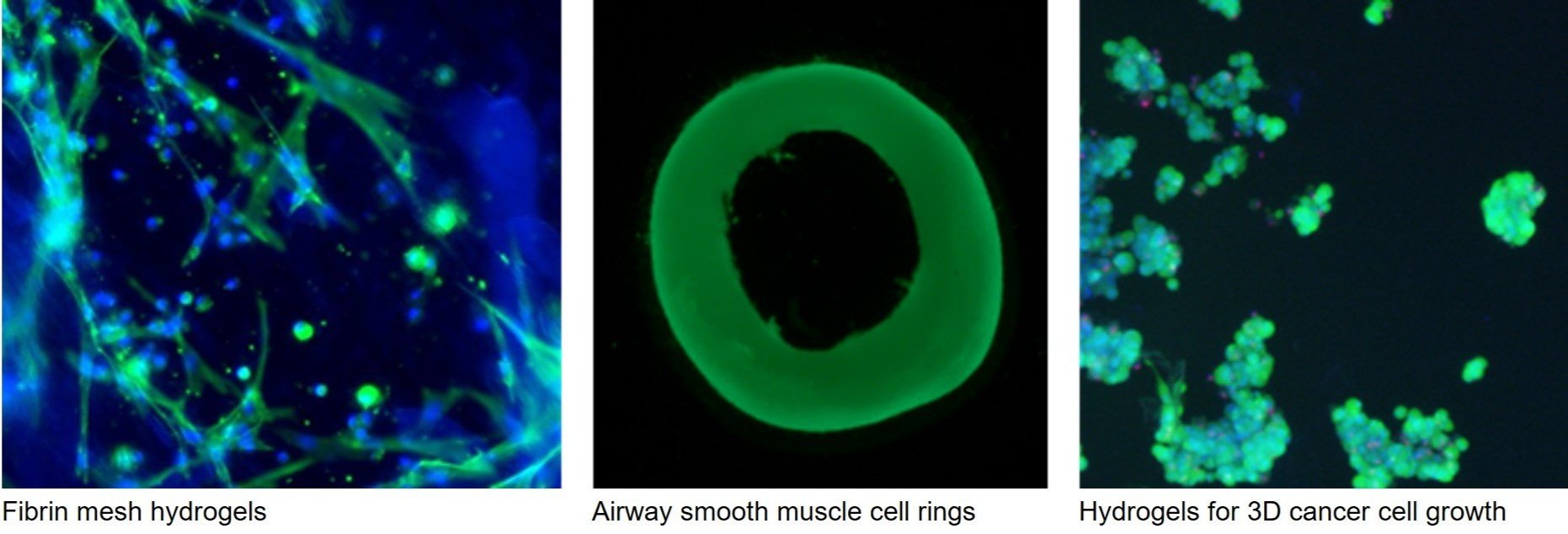

Tissue Engineering

Tissue-engineered constructs that are inexpensive, customizable, easily/rapidly fabricated, and made from accessible materials are required to improve in vitro organ models and clinical tissue replacement therapies. To provide these capabilities, we are researching and characterizing a variety of new systems for rapidly fabricating tissue-engineered constructs.

Advanced Fiber Manufacturing

We are developing a process for fiber manufacturing called contact drawing, which is similar to how fibers are made in nature by spiders and certain insects, and relies on the adhesion of a viscous fluid to two surfaces and cohesion within the liquid due to the presence of polymer entanglements. During fiber formation, protein additives capable of self-assembly become aligned with the polymer fiber, and upon hydration in an appropriate buffer, the templating polymer dissolves leaving behind a stable protein fiber for applications in tissue engineering and regenerative medicine. Non-protein additives can also be incorporated in contact drawn fibers for applications in drug delivery and filtration.

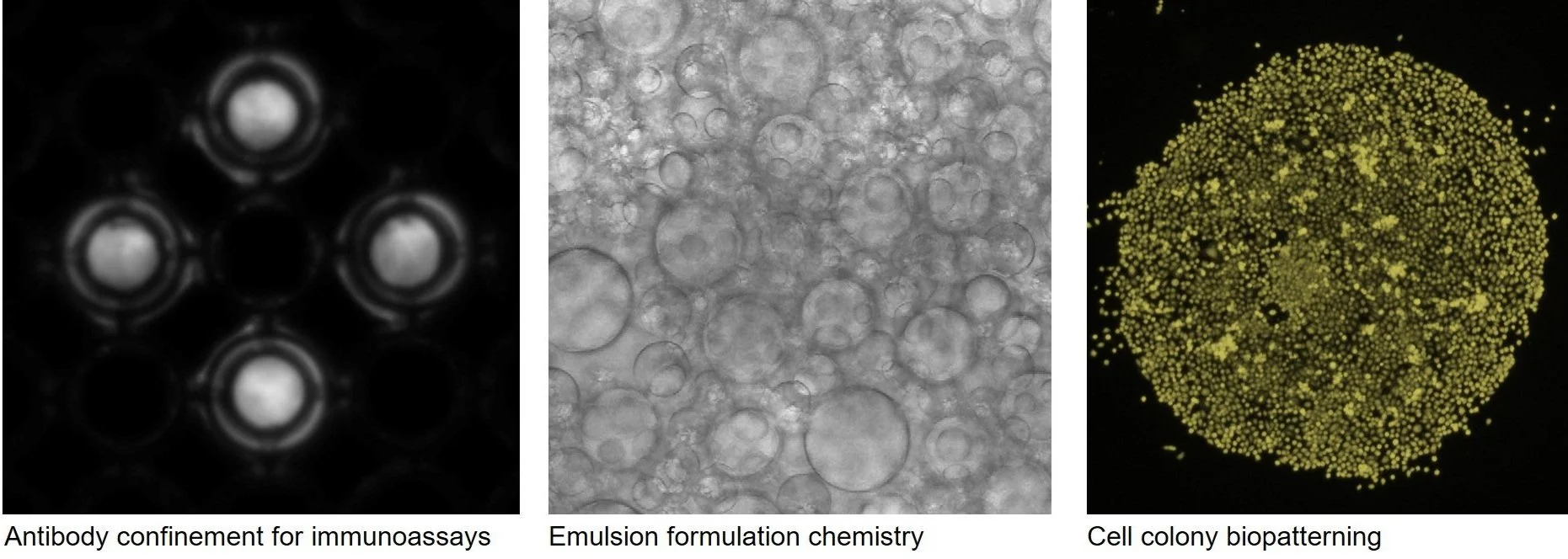

Liquid-Liquid Phase Separations

Aqueous two-phase systems (ATPSs) form when solutions of two incompatible polymers are mixed together at high enough concentrations. These system have traditionally been used for biomolecule and bioparticle separation from crude mixtures. We are exploring the fundamental physicochemical properties of a variety of newly-discovered ATPSs. We are also exploring additional applications for these interesting polymer systems in biopatterned cell based assays and high throughput biomolecular assays.